If you’ve ever stood in a walk-in staring at a case of produce that somehow aged ten years overnight, you know waste is one of the most maddening (and expensive) problems in foodservice. Everyone talks about cutting it. Nobody really has time to babysit it. That’s why AI has started to get attention — not because it’s flashy, but because it finally gives operators a way to see what’s actually happening behind all the chaos. Instead of guessing how much to prep or crossing your fingers on an order, AI tools help you make decisions with information you didn’t have before. Think of it as another set of eyes in the kitchen, only this one doesn’t clock out.

How AI is Transforming Food Waste Management

The biggest shift AI brings is clarity. Waste used to be something you noticed after the fact. A full trash can. A pan of unused sides. That “why did we buy this much lettuce?” moment. AI flips that around. It pieces together trends from your sales, usage, delivery schedules, and even patterns you didn’t realize you had. Suddenly you see the days when your prep is always too high, or the items that consistently spoil earlier than expected. You’re not reinventing your entire operation — you’re just reacting sooner because the system taps you on the shoulder before the mistake costs you money. That alone changes the game.

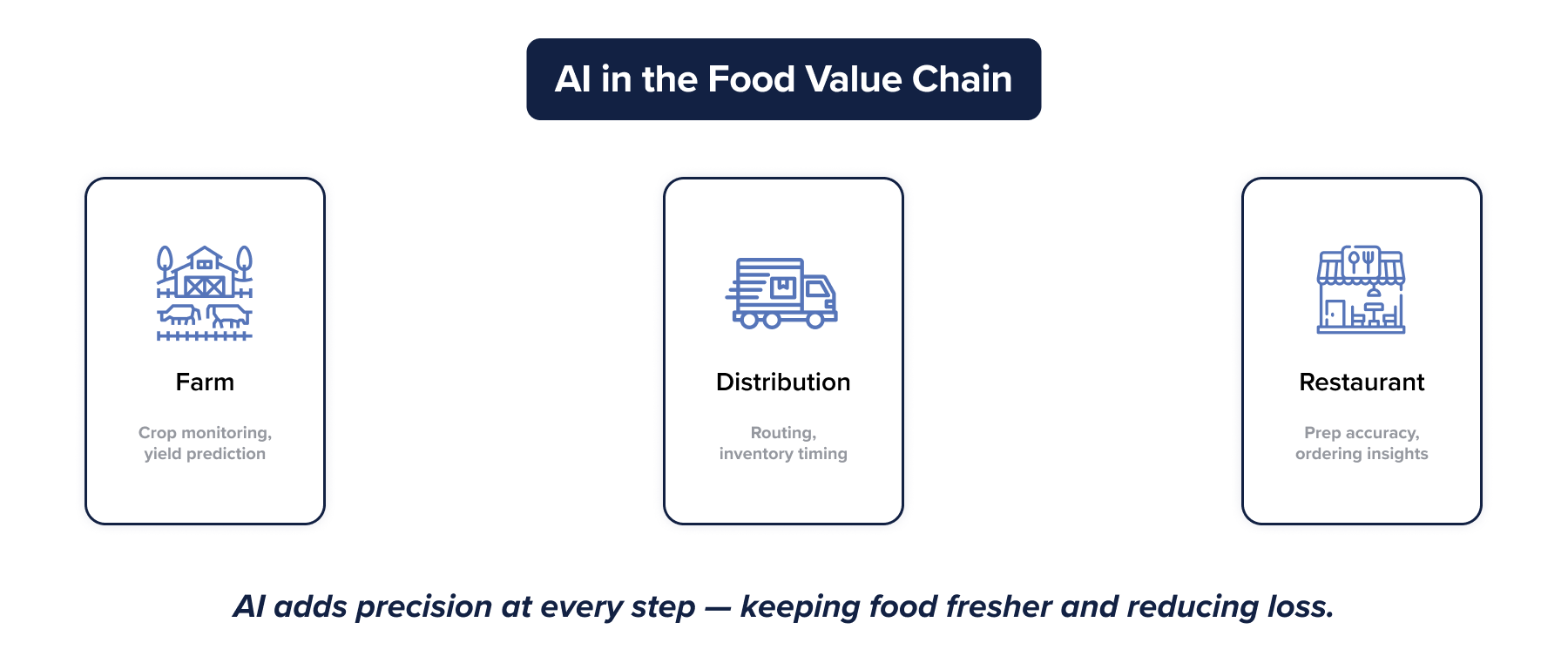

AI Applications Across the Food Value Chain

AI shows up in different ways depending on where you sit in the industry.

Agriculture and Production

Growers use AI to figure out when crops are actually ready and how much they’ll realistically produce. Instead of over-harvesting “just in case,” the tech helps align output with what the market wants. Less extra product means less spoilage long before it even reaches a distributor.

Supply Chain and Distribution

Distributors lean on AI to prevent inventory from sitting too long or moving through the wrong routes. The tech notices temperature risks, slow-moving items, and demand swings that humans often catch too late. When trucks move smarter, food stays fresher.

Retail and Restaurants

This is where operators really feel it. AI helps teams prep tighter, place better orders, and notice which ingredients tend to end up in the trash. It also flags portion inconsistencies and tells you when you’re prepping too much for certain menu items. Small tweaks here add up to major savings.

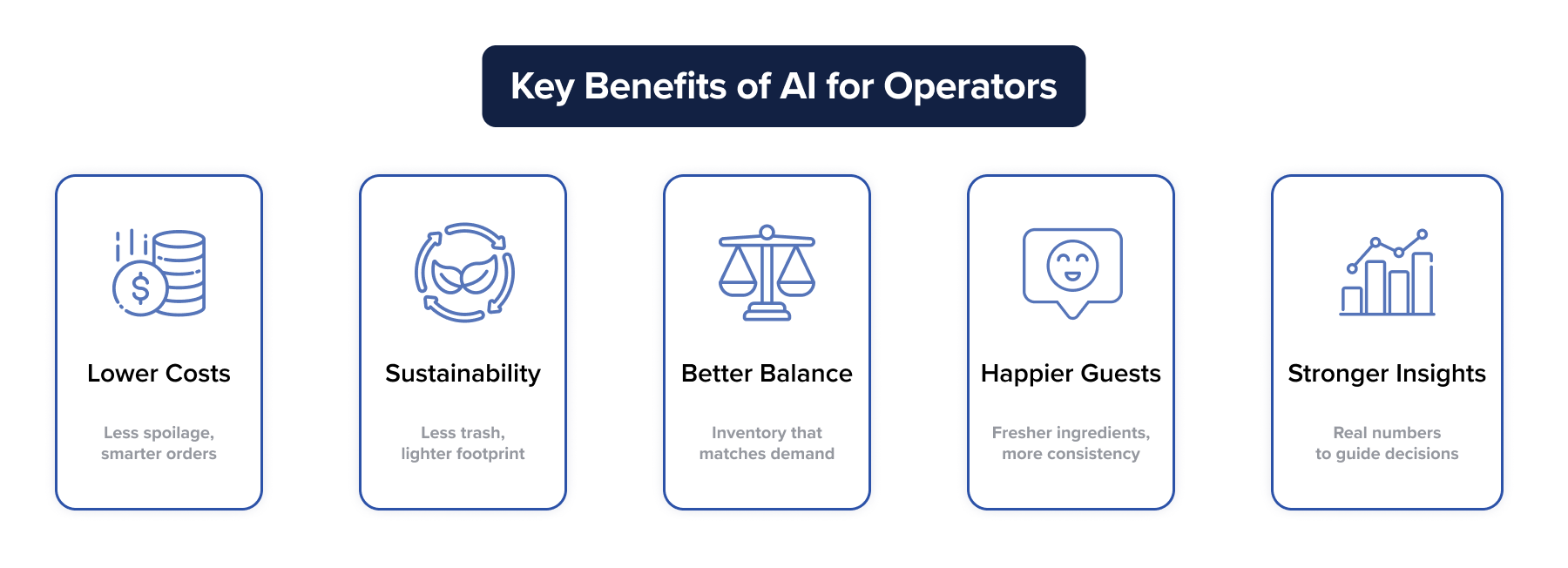

Key Benefits of Using AI to Tackle Food Waste

The biggest wins show up in the day-to-day.

Lower Costs

You waste less product, buy fewer emergency fills, and stop over-ordering out of fear. AI helps tighten ordering habits so you’re not tying up cash in inventory that won’t move.

Enhanced Sustainability

Better planning means fewer ingredients piling up in the trash, which is something guests absolutely pay attention to these days. And when your team actually uses what they buy, you naturally lighten your environmental impact without making a big production out of it.

Improved Supply-Demand Balance

You carry the amount of product your menu and volume truly require, not the amount you think you need. This steadier rhythm keeps your storage areas cleaner, leaner, and easier for teams to manage.

Increased Customer Satisfaction

Fresher ingredients and fewer stockouts mean smoother service and better meals. When kitchens are prepped accurately, the guest experience becomes more consistent from shift to shift.

Measurable Data Insights

Instead of relying on gut instinct alone, you get numbers that show exactly where waste is creeping in. These insights help operators set goals, track progress, and make smarter decisions every single week.

Challenges to Watch Out For

AI works, but adopting it isn’t a snap-your-fingers situation.

Cost of Implementation

Some tools require an initial investment, and operators need to decide whether the long-term savings justify the spend.

Need for Data Quality and Integration

If your systems don’t communicate or you have spotty data, AI can only do so much. Clean inputs matter.

Skill Gaps in Food Operations

Teams may need a little training to understand what the numbers mean and how to adjust their routines.

Privacy and Ethical Considerations

Any tech that touches operational data needs to be handled with care and transparency.

Scalability for Small Businesses

Smaller operations may struggle with budgets or bandwidth, even if the tech could help them the most.

The Bottom Line

AI doesn’t magically eliminate waste, but it gives operators something they’ve always needed: a clearer picture of what’s going on. It helps you plan better, prep smarter, and stop losing money in the places you weren’t even looking. As the technology becomes more accessible and built directly for foodservice, it’s turning into a real advantage for operators who want fewer surprises and more control. Waste may always be part of the business, but with AI, it doesn’t have to dictate the budget.

Ready to cut waste with better data and smarter tech? Contact us to see how InsideTrack can help.