If you run a restaurant, hotel, campus dining program, or healthcare foodservice operation, you already know one truth: your supply chain never takes a day off. Orders are flying in, products are moving out, prices are shifting, vendors are juggling shortages, and your team is trying to keep all the plates spinning—literally.

Buried inside all that movement is something incredibly valuable: your supply chain data.

Most operators aren’t short on data. The challenge is figuring out what it all means and how to use it to make smarter, more profitable decisions. When you can finally see the full picture, you don’t just stay ahead—you stay in control.

This guide breaks down what supply chain data actually is, why it matters, and how technology like InsideTrack helps operators turn raw numbers into real operational advantages.

What Exactly Is Supply Chain Data?

Supply chain data is every piece of information tied to how food and supplies move through your business—from the moment you buy something to the moment a guest enjoys it.

For foodservice, this data includes:

- Purchasing information

- Pricing and contract details

- Vendor and distributor performance

- Product specs and substitutions

- Inventory and usage

- Fulfillment timelines and delivery accuracy

It’s basically the “GPS system” behind your foodservice operation—the thing that shows you where everything is going and why it matters.

Why Your Supply Chain Data Matters

If you’ve ever walked into a walk-in cooler and wondered how you somehow ran out of the one item you swore you ordered, you already understand why supply chain data matters. It’s the behind-the-scenes truth-teller of your operation. When you can see what’s really coming in, going out, and changing on the back end, you get a clearer picture of where things are working—and where they’re quietly leaking money.

Here’s what strong supply chain visibility actually helps with in the real world:

- Keeping the right amount of product on the shelves. Nobody likes the guessing game between overstocking and running out mid-service. Good data helps you hit the sweet spot more consistently.

- Keeping costs from drifting upward without you noticing. Small price bumps, missed credits, or product swaps add up fast. Data makes those changes easier to spot and question.

- Staying ahead of quality issues. When something’s off—delivery times, condition of product, order accuracy—the trends show up in your data long before they become bigger problems.

- Smoothing out day-to-day operations. There’s a big difference between running reactively and running intentionally. Clear data helps you plan instead of scramble.

- Understanding demand before it hits. Patterns in your ordering and sales can help you anticipate what’s coming, whether it’s a busy weekend or a slow stretch.

- Knowing how your suppliers are performing. You can see who’s reliable, who’s inconsistent, and where small issues are starting to affect your bottom line.

- Protecting your operation from risk. Compliance, substitutions, product changes—they all show up in your data. The more visibility you have, the easier it is to stay aligned with standards and avoid surprises.

How Operators Can Manage Their Supply Chain Data More Effectively

If you want clear insights, you need clean data. Here are simple ways operators can start strengthening their data foundation:

5 Practical Steps to Improve Your Data Management

- Use a centralized system instead of juggling multiple spreadsheets.

- Standardize your formats so every location is speaking the same “data language.”

- Automate data collection whenever possible—manual entry leads to noise.

- Get real-time visibility instead of relying on last month’s purchase history.

- Use analytics tools that help interpret what your numbers actually mean.

Doing all of this manually is…well, unrealistic. This is where advanced technology changes the game.

The Tech That Actually Helps You Get More Out of Your Supply Chain Data

Most operators aren’t asking for “futuristic tools” or “advanced analytics.” They just want fewer surprises, cleaner information, and enough visibility to make decisions without guessing. The right technology doesn’t complicate things—it simplifies them.

Here’s what that looks like in practice:

Making Your Data Speak the Same Language

Every distributor has their own naming quirks, item numbers, and formats. When you pull everything into one system and standardize it, suddenly you can compare apples to apples instead of trying to decode mismatched spreadsheets. It’s the foundation for every other insight you’re trying to get.

Spotting Price Shifts Before They Hit Your Wallet

You know the feeling—you open an invoice and realize a key item jumped in price without warning. Predictive tools catch those patterns earlier so you can prep, negotiate, or pivot before it affects your food cost.

Getting Better at Predicting What You’ll Actually Need

Demand isn’t random, even if it feels that way. Machine learning looks at your ordering patterns, seasonality, and menu mix to help you plan inventory with more accuracy. Less waste, fewer last-minute “uh oh” moments, and more stability in your daily operations.

Seeing What’s Happening in Real Time

Delivery delays, substitutions, shorted items—those ripple through your operation fast. Real-time visibility helps you identify issues the moment they pop up so you’re not finding out about a problem at the start of service.

Understanding How Your Operation Is Really Performing

Dashboards and analytics take all that information and show you where things are going well and where things need attention. Think of it like getting a weekly pulse check on your supply chain without having to dig for it.

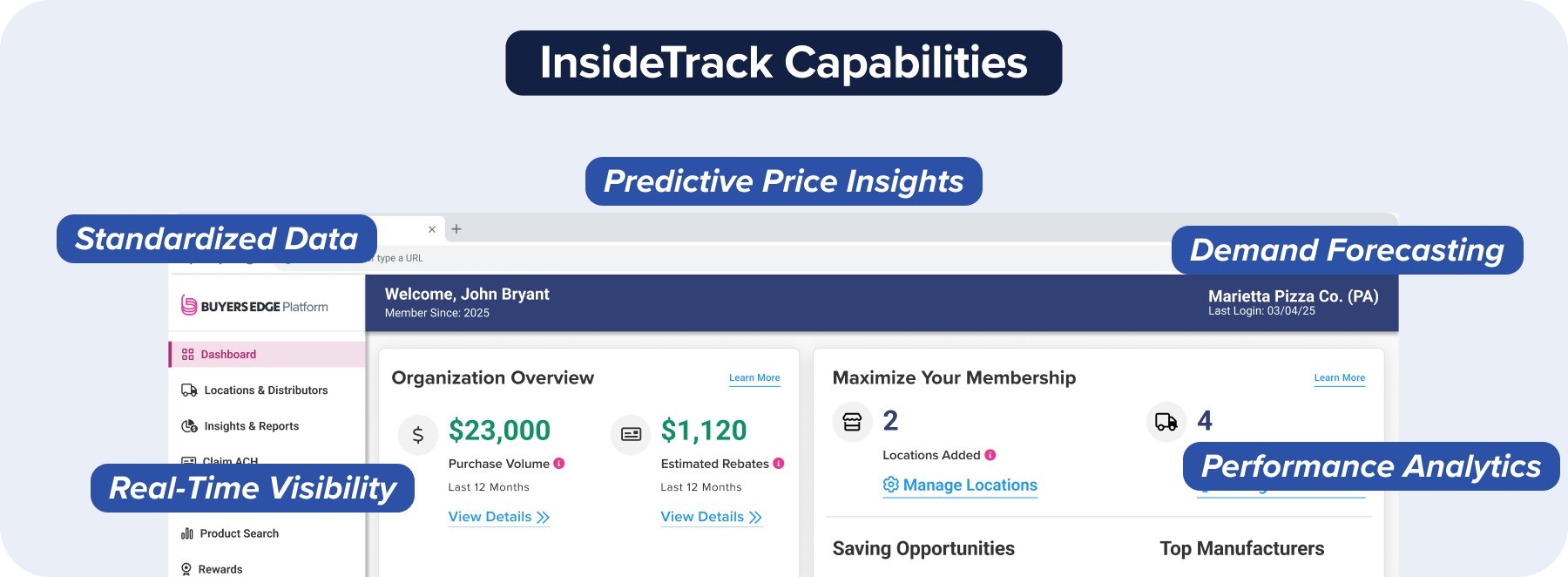

How InsideTrack Turns Your Data Into a Competitive Edge

InsideTrack takes everything above and brings it to life with a powerful data engine built specifically for foodservice. You don’t have to wrestle with spreadsheets or guess what’s going on—you get visibility, clarity, and opportunities at your fingertips.

Here’s how InsideTrack helps operators extract more value from their data:

1. Standardized, Clean Data

InsideTrack automatically standardizes and normalizes your purchasing data so you’re not comparing apples to…well, slightly different apples with new item numbers.

2. Predictive Price Insights

Spot rising costs before they land on your invoice and protect your margins with smarter buying strategies.

3. Smarter Demand Forecasting

Machine learning models help you stock accurately, reduce waste, and stay prepared for what’s coming next.

4. Real-Time Supply Chain Visibility

Track what’s happening across your entire operation—with the ability to act fast when something needs attention.

5. Performance Analytics That Actually Make Sense

InsideTrack turns complex data into straightforward dashboards that highlight what’s working, what’s not, and where to adjust.

Operators who use InsideTrack don’t just “see” their data—they leverage it to make higher-margin decisions every single day.

And Don’t Just Take Our Word for It

This is where you’ll drop in testimonials, quotes, videos, or real operator stories—anything that brings the human experience to life.

Ready to Put Your Supply Chain Data to Work?

InsideTrack gives you the visibility, clarity, and confidence to run a smarter, leaner, more profitable operation.

Fill out the form below and an InsideTrack expert will reach out to you.